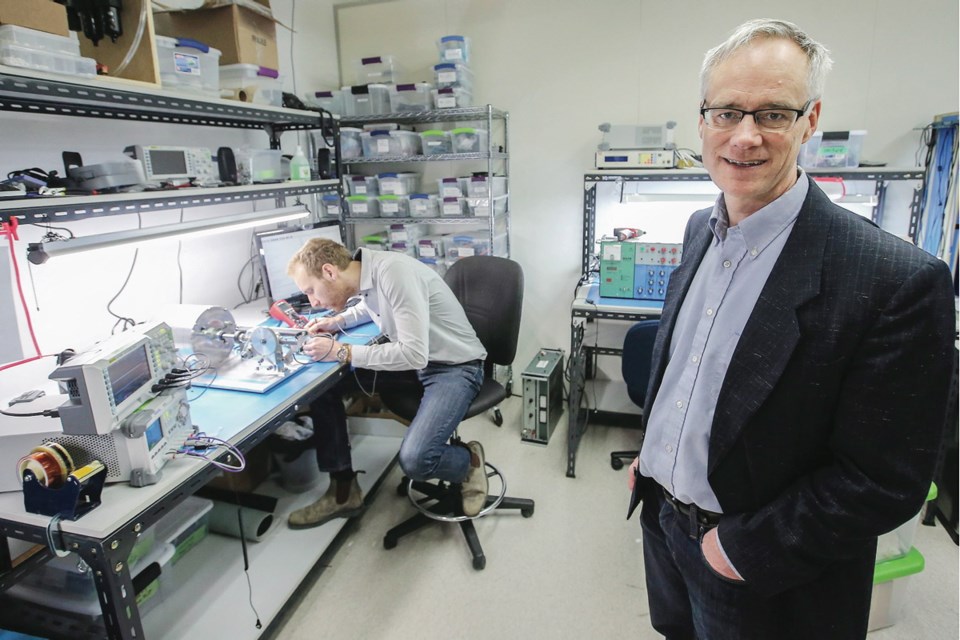

Victoria’s StarFish Medical is on the front lines of an effort to manufacture 30,000 ventilators in Canada to meet an expected shortage of the life-saving medical equipment in response to the COVID-19 pandemic.

StarFish, Canada’s largest medical-device design company, is working with the federal government and other companies to design, develop and produce ventilators.

The company, which is working on one of four initiatives to produce ventilators, will be responsible for the delivery of at least 7,500 of the 30,000 to be manufactured, said founder and CEO Scott Phillips.

Phillips said the company is responsible for the program up to the delivery. The other design partners will be chosen by and managed by StarFish, while the majority of the manufacturing will likely be done in Ontario and Manitoba.

“We’re in the advanced prototype stage, moving quickly toward clinical [and regulatory] testing,” he said. “We’ll be moving aggressively toward manufacturing at the same time as we’re doing clinical and regulatory.

“We would love to have units available in a couple of months.”

Mechanical ventilation, or breathing machines, are used in severe cases of COVID-19, which can compromise breathing. B.C. is using the machines early and aggressively to try to prevent more severe cases, in which mucus and fluid build up in a patient’s lung, requiring intubation, an invasive procedure where tubing is run through the trachea and nasal passages and can cause other complications and increase risk of transmission.

The province has between 1,400 and 1,500 ventilators, including new and refurbished ones added over the last week, Health Minister Adrian Dix said Tuesday.

“We would naturally expect a share of additional ventilators that were purchased, but right now, our goal is to ensure, by being 100 per cent committed to the measures that have been adopted by Dr. [Bonnie] Henry, that our current stock of ventilators will be sufficient,” Dix said.

Henry, the provincial health officer, said she hopes the ventilators won’t be needed if residents keep physically distancing themselves from all but household contacts in an effort to flatten the rate of new COVID-19 cases.

“If we keep doing what we’re doing, we may not need them,” Henry said Tuesday. “But we may need them with another wave in the future, so all of this is us working together across the country.”

StarFish got a call three weeks ago from Next Generation Manufacturing Supercluster, a group of businesses, post-secondary institutions and non-profits aimed at building up next-generation manufacturing capabilities, to say it had been chosen to design a ventilator model that can be constructed quickly and reliably in Canada.

The design builds on technology developed by Dr. Magdy Younes of Winnipeg, a world-renowned respiratory specialist and innovator.

The so-called original Winnipeg Ventilator was licensed and used as the basis for commercial ventilators throughout the 1990s and 2000s, including during the 2003 SARS epidemic.

“Since then we’ve been racing to take an old design, which worked very, very well, and bring it up to date and make it manufacturable,” Phillips said. The newer commercial design that existed as a prototype wasn’t available to the Canadian firm.

“Now we’re rapidly turning that into a very targeted product just for the COVID-19 crisis that can be produced efficiently and quickly and cost effectively.”

Asked in his daily briefing about the number of ventilators to be produced, Prime Minister Justin Trudeau said the government needs to be ready for every circumstance.

“The opportunity to make sure that we have ventilators available if we need them is going to be extremely important,” Trudeau said. “So, we have told these companies across the country who have put up their hands to go ahead and get building ventilators as quickly as possible and as many as possible in case we need them in Canada.

“We certainly hope that we won’t be needing all those ventilators, but we also know that there are countries around the world where they are not able to tool up local production to create more ventilators.”

Any extra ventilators can be shared with countries that are facing more difficult circumstances, since the global supply is already stretched thin, Trudeau said.

Last month, the federal government announced $2 billion in funding to support testing and purchasing of ventilators and protective personal equipment in Canada.

Nearly 5,000 Canadian companies have offered their expertise and services to the federal government’s Plan to Mobilize Industry to produce medical equipment and protective gear for health-care workers.

“This is exactly the kind of innovative, collaborative thinking we need to respond to this rapidly evolving pandemic,” Trudeau said. “By increasing our support for secure Canadian sources of needed materials and equipment, we will be able to help our health-care workers protect themselves, treat patients and slow the spread of this virus.”

Ventilators being made by other firms include those targeted for the military or use in ambulances.

Phillips compared making the ventilators to the building of Spitfires in the Second World War, meaning they are not built to last forever but to address a particular and immediate need.

“I think it’s very heartening that so many companies are willing to step up and devote their resources to this problem,” he said. “Honestly, a year from now, we’ll have lots of ventilators; we’re solving a problem right now in Canada. And if this helps some companies re-tool to develop other capacity, that would be wonderful.”