The manufacturing of face shields for health-care workers on the front lines of the COVID-19 pandemic gears up today through Camosun College’s innovation centre, where 9,000 will be made over the next few weeks. Using a design developed at Camosun, more than 124,000 shields will be made by the end of May through a Victoria-based company.

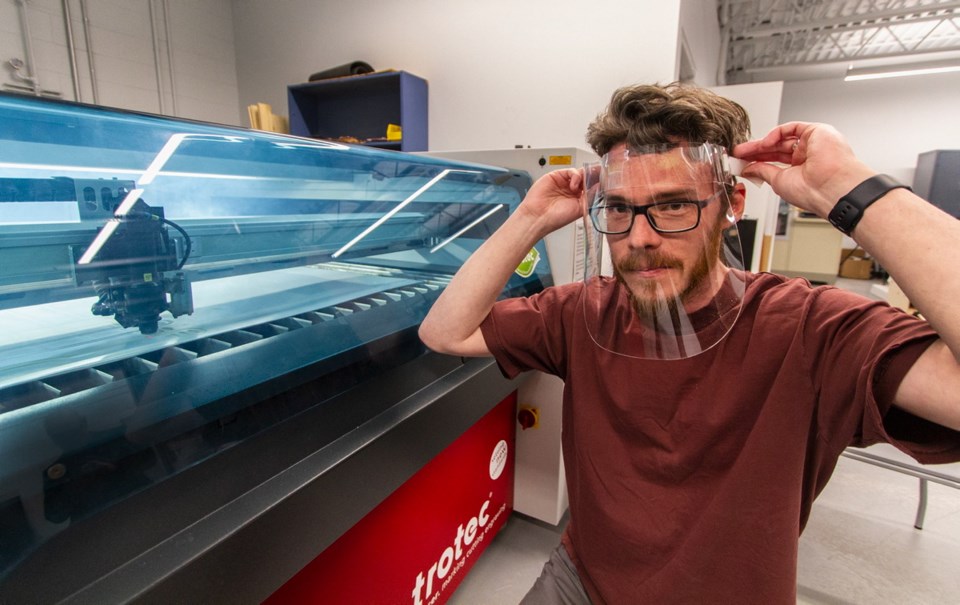

The medical-grade transparent thermal plastic face shields, designed with Island Health, span from a person’s eyebrows to chest, and fit over goggles, glasses and medical masks to try to prevent, in this case, the novel coronavirus from infecting health care workers.

“They are the first line of protection,” said Richard Gale, director of Camosun Innovates, the applied research and innovation arm of Camosun College.

“We’re trying to respond to the immediate crisis with solutions that can be shared broadly and have an impact beyond the local.”

Working at their campus facility and in collaboration with industry partner AP Plastics, Camosun will manufacture the 9,000 masks to fill an urgent need at Island Health.

The college and health authority inked the deal on Monday night.

“We’ve been working on spec just under the assumption that this was going to be needed no matter what,” said Gale.

That deal and the initial production of 9,000 masks will also allow AP Plastics time to retool its manufacturing facility in Calgary to make the masks in greater volume.

Camosun applied research technologist Matthew Zeleny, serving as the co-ordinator of the COVID-19 response activities, designed the face shield. Once Island Health reviewed the prototype it requested “some tweaks” including lengthening the shield to stretch to the wearer’s chest, said Gale.

Zeleny replaced the face shield’s standard plastic headband with a strap. This was done to speed up production and enable the entire mask to be made in one go with a laser cutter. Camosun Innovates owns a laser cutter.

“Basically for us, it meant that instead of doing roughly nine or 10 a day we could be doing roughly 90-100 a day and we knew that the need was growing exponentially and so we contacted AP Plastics to make sure we could source the materials,” said Gale.

AP Plastics, based in Victoria on Simcoe Street, found the transparent plastic as well as the strapping. Materials such as plexiglass were considered but were too inflexible. The masks are manufactured using high-grade polyethylene terephthalate, called PETG. Both pieces can be put in a dishwasher for cleaning, said Gale.

“The shield is designed with a built-in buckle so it’s adjustable and compatible with a wide range of strap materials for the greatest flexibility in real-world conditions,” said Zeleny.

The masks, which can be flat packed, will be cut with a laser printer at Camosun.

“When it gets sent to Island Health it will come in packages that include everything and they will just have to assemble it,” said Gale. “Our philosophy is to try to design a new process so that others can benefit.”

The Camosun Technology Access Centre is an applied research and innovation centre providing access to specialized technology, equipment and expertise to local and regional companies. It’s funded by the federal government.

In making 9,000 face shields, it hopes the design, which will be shared, could be used in other parts of Canada.

“The British Columbia government has designated us an essential service, not only in terms of research activity but also to help our industry partners as they support the health care sector,” Gale said.

“When the pandemic hit and we saw reports of health-care workers in urgent need of personal protective equipment, we reached out to Island Health and offered to help.”

The University of Victoria, working with local entrepreneurs in a separate arrangement with Island Health, is assembling and distributing a different design of face shields.

Island Health says it has been working with Vancouver Island post-secondary institutions and other local producers to develop 3D printed and laser-cut plastic prototypes for face shields that meet health system standards.

“We are grateful for the innovative work being done by Camosun College to develop face shields that meet the health system standards,” said Leah Hollins, Island Health board chairperson.

“This partnership is an example of how community efforts and expertise can result in direct support for health-care workers.”