A Victoria company is building vertical wind tunnels to feed the latest craze in “high-adrenaline” sports.

Bodyflight Mobile Systems Inc. and Team Fly Zone, which produce mobile machines that simulate the skydiving experience, ramped up production this week on its first international orders.

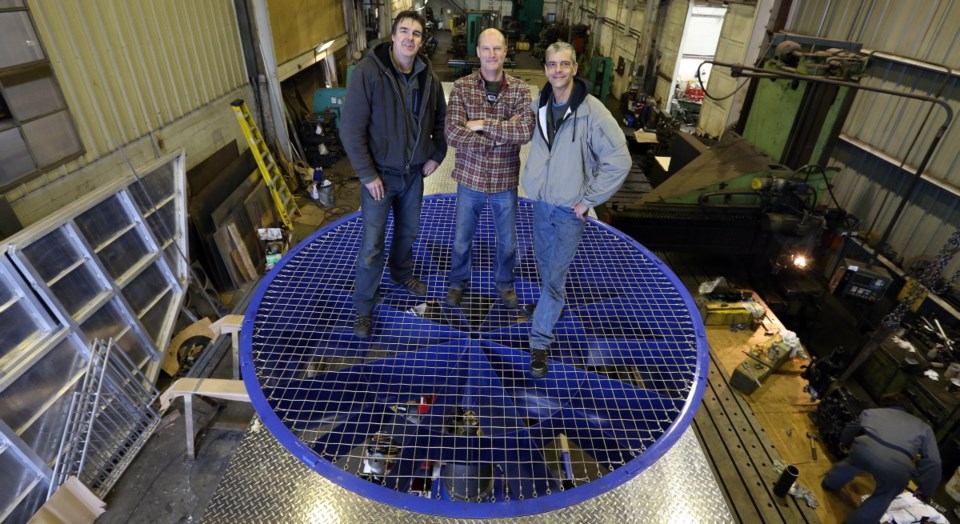

Peter Zaoralek, president of the Bodyflight group of companies, said steel and aluminum fabrication is underway at United Engineering on Harbour Road to produce a Fly Zone wind tunnel for a company in Taiwan. A second machine is slated to begin later this month for a customer in Guam, and there are “pending orders for several more,” Zaoralek said Monday.

The company said it uses vertical tunnel technology to create winds as high as 230 kilometres per hour and a flying experience that simulates a skydive freefall without the risks and costs associated with skydiving.

The machines are built on frames that can be mounted on trailers and hauled to events. They take six months to build and are valued at between $500,000 and $1 million, according to Bodyflight. The company said it is using local labour and the projects are made up of 80 per cent Canadian-made components.

Zaoralek has been operating Fly Zone since 2009 at special events on the Lower Mainland, Calgary, the Bahamas and recently in New York aboard a cruise ship. He is currently negotiating a property acquisition on the Lower Mainland to set up a permanent Fly Zone site.

Users experience the rush of human flight in a transparent acrylic flight chamber. However, new designs now under construction will have a convertible option for open-air flight. Flyers are now able to fly in the open above the tunnel opening for a more realistic simulation of free fall flight. The new designs incorporate a number of advancements such as convertible safety cushion flight deck, self-levelling technology and full hydraulic deck systems, with much of the equipment hand built with low-weight and non-rust aluminum components.

“We are getting inquiries from around the globe. People are becoming more comfortable with the technology and they are ready to make an investment. It is a growth industry,” said Zaoralek.

United Engineering and Harjim Industrial Services are building the chassis and custom components, and other B.C.- based firms are adding engineering expertise and specialized parts. About 15 workers are being employed for the latest projects, Zaoralek said.

“We are assembling the entire system in Victoria,” he said. “We feel the time is right to build this as a strong niche industry in Victoria.”

The Taiwan simulator is scheduled to launch early this year. Zaoralek said the Taiwan clients trained with the Fly Zone team in Calgary over two weeks and an agreement was drafted to build the machine. Once it is built and tested in Victoria, it will be shipped overseas for the second phase of training.

A semi-portable, multi-level system for a customer on the Pacific island of Guam is on schedule for a mid-2014 delivery. A former military and businessman and Skydive Drop Zone owner will operate the system as a business venture for tourism, local and military use.

Stephen Winter, head of research and development at Bodyflight, streamlined the original mobile flight design. The new systems use advanced Finning CAT Tier 4 diesel engines, considered one of the cleanest-burning diesel engines available.

Fly Zone transported a system to Manhattan in the spring to be part of Royal Caribbean’s unveiling of the design plans for the newest cruise ship, which will include a skydive simulator system. The company also travelled to Calgary to work with Alberta Skydivers Ltd. on their local drop zone and took part in filming a movie sequence for an undisclosed upcoming film.

bodyflightcanada.com