|

|

Click on the cover to read the fall 2014 issue of Capital magazine online |

Products manufactured in the capital region can crop up just about anywhere.

Visit an exotic location and you might be island hopping in a Twin Otter airplane built on the Saanich Peninsula. Hiking boots made by Viberg may stride by on the streets of New York or Tokyo. A trophy fish in the Bahamas or Haida Gwaii may be landed with an Islander Reel. And you just might be on a train in Beijing with some of its automated features designed and manufactured in Central Saanich.

While everyone seems to agree that manufacturing accounts for a significant chunk of Greater Victoria’s economy, just how significant isn’t really clear. That’s why the Greater Victoria Economic Development Agency and other organizations are undertaking a comprehensive survey to get a handle on what is made here and how much it is worth. Results are expected this fall.

Most local manufacturing companies are small and supply niche markets. Many are specialized and part of the technology sector. It’s estimated there are 120 manufacturing firms in the region. On the Saanich Peninsula alone, estimated annual revenue from the sector tops $650 million, with a payroll of $110 million for 2,200 employees on the front lines.

Manufacturing development is a lesson in evolution. Each venture finds its own way to startup and grow. Financing can come from friends and family, banks or angel investors. Some make it. Some don’t.

Post-secondary schools are turning out skilled workers and acting as hothouses for new companies.

Favourable tax rates, tax credits through the Industry Training Authority, a booming natural-resource industry and proximity to markets such as India and China all support manufacturing.

But there are challenges, including the return to the provincial sales tax last year, currency fluctuations and competition from other jurisdictions that provide substantial incentives to attract investment money.

Reels keep on rolling

Fishermen love bragging about catching a big one. Add a locally made Islander Reel to their gear and that’s something else to crow about.

Fishermen love bragging about catching a big one. Add a locally made Islander Reel to their gear and that’s something else to crow about.Islander Reels have been made in Victoria for more than two decades. Every year, between 3,500 and 4,000 reels roll off the lines at JS Foster Corp., said Elliot Williams, who manages the Islander division.

The coveted, smooth-running reels come in a variety of colours to match custom rods and increasing demand, Williams said. Gold is the “flagship colour.”

The company is owned by Jack Foster and is part of JS Foster, a Saanichton company that makes machined components for several industries — from subsea instruments to high-pressure gas systems and aerospace parts.

The company, with 12 employees, uses lathes and milling machines to produce intricate, precision parts, and it designs and engineers the components from the prototype stage to final volume production.

Islander manufactures 22 models of reels, sold through dealers in Canada and the U.S. Most customers are in the two countries, but there’s also demand from other nations. Some customers like to buy them for occasions such as birthdays and anniversaries and have them engraved.

Suggested retail prices for fly reels are $340 to $825. Mooching and centre-pin reel prices range from $425 to $650. Revenue details are kept confidential, but Williams said “sales are strong.”

(Photo: Kate Foster shows off Islander Reels.)

Boots for the ages

Walk into Viberg Boot Manufacturing Ltd. on Boleskine Road in Saanich and you’ll get an immediate whiff of leather and hear muffled sounds of hammering.

Walk into Viberg Boot Manufacturing Ltd. on Boleskine Road in Saanich and you’ll get an immediate whiff of leather and hear muffled sounds of hammering.

Every day, 30 to 35 high-quality pairs of boots are turned in the 8,600-square-foot manufacturing space behind a retail shop, said Jason Viberg.

The 83-year-old business uses skills passed down through generations, as well as modern technology to track in-house production and to market its boots.

Europe, Asia and North America are key markets.

Boots are sold wholesale to between 250 and 275 retail outlets and to individual customers worldwide.

The third-generation, family-owned business has 27 staff, including four Vibergs — brothers Jason and Brett and parents Leslee and Glen.

Viberg was founded on work boots, but today the blue-collar footwear shares the revenue spotlight with men’s fashion boots. Each has its own website. Workboot.com was set up a decade ago.

Viberg.com started selling fashion boots about a year ago and the line has taken off, Jason Viberg said. Wholesale sales account for 55 per cent of business, with retail at 45 per cent.

When it comes to fashion, “we almost sell it as fast as we can put it up online,” he said. “It just seems to keep on growing. It definitely hasn’t peaked. It really makes a difference to our bottom line.”

(Photo: Viberg tailors for work, fashion.)

Train talking

Central Saanich technology manufacturer Quester Tangent provides a translation service that allows transit trains to talk to the people who operate them. Its monitoring and control systems are used in subway and high-speed train fleets around the world, including SkyTrain in Vancouver and commuter lines in Atlanta, Boston, Philadelphia, New York City, New Jersey and Washington, D.C., as well as Beijing and Kuala Lumpur.

Central Saanich technology manufacturer Quester Tangent provides a translation service that allows transit trains to talk to the people who operate them. Its monitoring and control systems are used in subway and high-speed train fleets around the world, including SkyTrain in Vancouver and commuter lines in Atlanta, Boston, Philadelphia, New York City, New Jersey and Washington, D.C., as well as Beijing and Kuala Lumpur.

The 31-year-old company designs and manufactures the monitoring and diagnostics equipment with 85 employees, including 39 engineers, many educated at the University of Victoria. “[The equipment takes] information, makes sure it is valid and then distributes it to decision makers,” said Bill Collins, company vice-president and chief operating officer.

For example, a system collects data, compiles information on the status of a train car to find out where a potential fault may exist and what can be done about it.

This includes monitoring circuit breakers, batteries and detecting ground faults.

It could also mean controlling windshield wipers, headlights and doors.

Or it might involve monitoring software that provides information on operating systems, on-board communications and other data about the fleet.

Quester Tangent’s annual revenue surpasses $10 million. The privately held company saw revenue growth of 20 per cent year-over-year between 2009 and 2013. In the next five years, revenues are expected to double.

“There’s a lot of potential for the train business to deliver, in North America in particular,” Collins said.

(Photo: Richard Lyne tests a rail engineer control panel at Quester Tangent.)

Viking’s flying high

Viking Air is the undisputed darling of the region’s manufacturing sector. And who can argue? The North Saanich company has 450 local workers, average wages of more than $30 an hour, international sales and the success of bringing the Canadian icon Twin Otter airplane back into production.

Viking Air is the undisputed darling of the region’s manufacturing sector. And who can argue? The North Saanich company has 450 local workers, average wages of more than $30 an hour, international sales and the success of bringing the Canadian icon Twin Otter airplane back into production.

Annual sales are “pushing $200 million,” said Dan Tharp, executive vice-president of operations.

Through salaries and services supporting their operation at Victoria International Airport, Tharp said Viking sends millions into the local economy every year.

The company has been instrumental in developing programs at Camosun and North Island colleges to train for its skilled workforce.

Viking has evolved from making airplane parts to modernizing the popular Twin Otter plane.

To date, 65 Twin Otters have been produced since 2009. Add in confirmed orders and the total reaches 100 sold to 26 countries.

This year, 24 custom planes will be built. Prices vary according to customer needs, ranging from $6 million to $10 million.

Twin Otters are produced through a massive manufacturing plant on Victoria Airport lands, with final assembly in Calgary, where another 150 workers are employed.

Viking is owned by local resident Sherry Brydson, through Westerkirk Capital, a Toronto-based company.

(Photo: Viking Air's Robert Kutzner works on a wing grid.)

Eyes on accessories

Today’s paddleboards and kayaks are sporting all sorts of accessories, including specialized mounts for cameras, fishing rods and global positioning systems.

Today’s paddleboards and kayaks are sporting all sorts of accessories, including specialized mounts for cameras, fishing rods and global positioning systems.

Increasing demand for the products is helping to reinvent product lines and propel sales for Scott Plastics Ltd. in Sidney, a company founded in 1952 that now employs 100 workers.

“We are incredibly busy right now,” said Robin Richardson, vice-president of operations. “I think the U.S. market is definitely picking up and stronger. Europe seems good. We are 15 to 18 per cent up this year on [sales, versus] last year. We are seeing some fairly significant growth. Part of that is due to some expanding markets in our canoe, kayak and paddleboard markets.”

He said a significant trend is big-game fishing off kayaks, which requires special mounts.

Scott’s annual sales are in excess of $15 million, Richardson said.

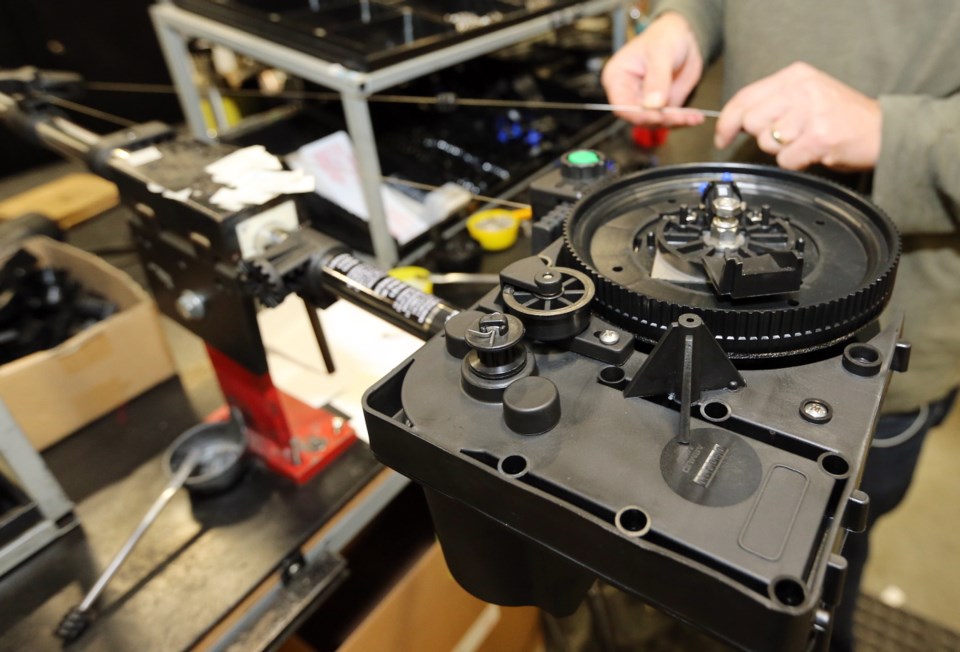

Founded by Blayney and Almeda Scott in 1952, the company has long been known for manufacturing marine equipment — including its famous downrigger, used extensively in the sport fishery — and has had a decades-long reputation for innovation. Three decades ago, Scott was turning out precision instruments for astronomers in Switzerland to use in spectroscopic analysis of stars.

Fishing gear, boating supplies and firefighting equipment are among its many products.

The firm also offers custom plastic moulding and tool-making services using high-tech software and equipment.

(Photo: The intricacies of an electric down rigger being made at Scott Plastics.)

Push plankton

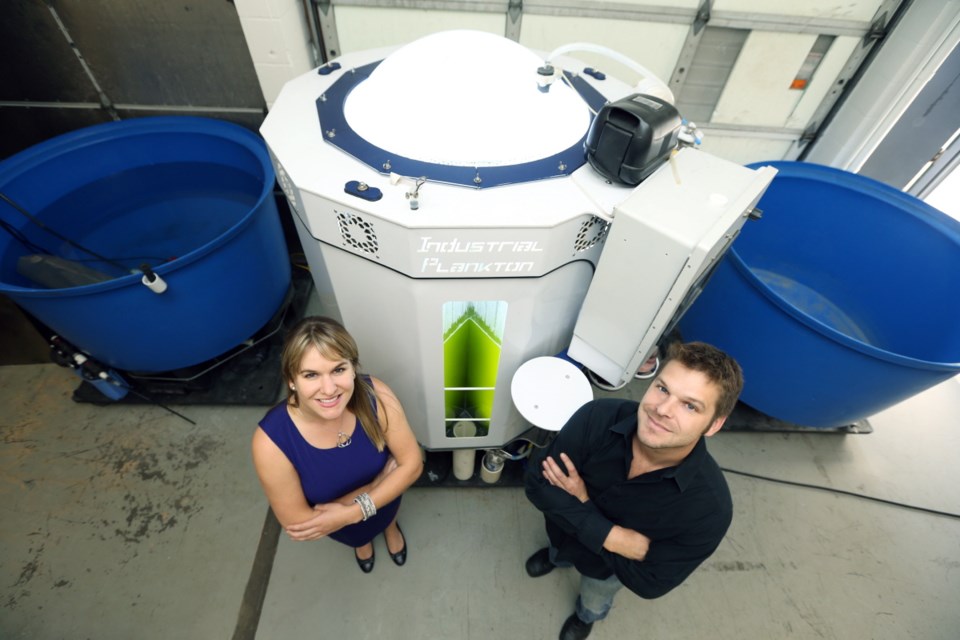

Industrial Plankton is wrapping up its second round of financing to expand the young technology company’s market beyond aquaculture and into nutraceuticals.

Industrial Plankton is wrapping up its second round of financing to expand the young technology company’s market beyond aquaculture and into nutraceuticals.

Siblings and University of Victoria graduates Ashley Roulston, 27, and Robert Roulston, 33, and their two employees build bioreactors in a Saanich business park.

Industrial Plankton shows what it takes for a start-up to get out of the gate with seed financing from family, friends and angel investors and using mentors in the local tech community. The company recently launched a new financing effort to raise between $250,000 and $500,000.

When the business started four years ago, it was known as Reef Safe Fish and won the B.C. Innovation Council’s New Ventures competition for its closed-loop, waste-recycling technology to produce food for penned fish.

Industrial Plankton changed its name to produce bioreactors for customers raising algae for shellfish hatcheries and now for bio-technology customers who want algae as an ingredient in nutraceuticals. A nutraceutical is a product isolated or purified from foods that is generally sold in medicinal forms not usually associated with food, according to Health Canada.

Industrial Plankton is targeting the larger biotechnology market because it sees plenty of sales potential. Ashley contacts biotech firms individually, saying about 90 per cent reply.

Like many Greater Victoria manufacturing firms, Industrial Plankton is targeting offshore markets. It has sold equipment in Australia and the United States. The aim is to produce 10 bioreactors per month.

(Photo: Ashley and Robert Roulston with bioreactors that raise algae.)

Making waves

The surf’s up at Anian, a lean — and definitely green — surfboard and apparel manufacturer on the edge of downtown Victoria. Long-time friends and passionate surfers Nick Van Buren and Paul Long, both 26, built their shop at 516 Discovery St., in December. Like any new business, Anian is striving to build its customer base and revenues, but it is also encouraging others to turn on to solar power.

The surf’s up at Anian, a lean — and definitely green — surfboard and apparel manufacturer on the edge of downtown Victoria. Long-time friends and passionate surfers Nick Van Buren and Paul Long, both 26, built their shop at 516 Discovery St., in December. Like any new business, Anian is striving to build its customer base and revenues, but it is also encouraging others to turn on to solar power.

They partly operate on solar now, but hope to be off the grid by the end of the year. To reach that goal, Anian is running a crowdfunding push by selling products to raise $12,000. Long said they want to turn off traditional power sources “to show other people it’s possible.”

Van Buren and Long raised the capital to open Anian through a construction firm they started in 2012. Each Anian owner is responsible for his own product line.

Van Buren makes surfboards selling for between $650 and $1,000. So far, he’s made 75 boards and is working “flat out.” He makes them to order for a customer base in B.C. and Alberta. That market could grow as more boards ride the waves and word travels in the surfing community.

Long designs shirts, jackets and other apparel, sourcing high-quality materials that are sewn by contractors in Victoria and Vancouver. Prices run from $25 to $130.

They are hoping to sell their clothing in retail outlets in Canada and the U.S. Van Buren also plans to make surfboards in fun designs using recycled wood.

(Photo: Paul Long and Nick VanBuren make surfboards and design clothing.)

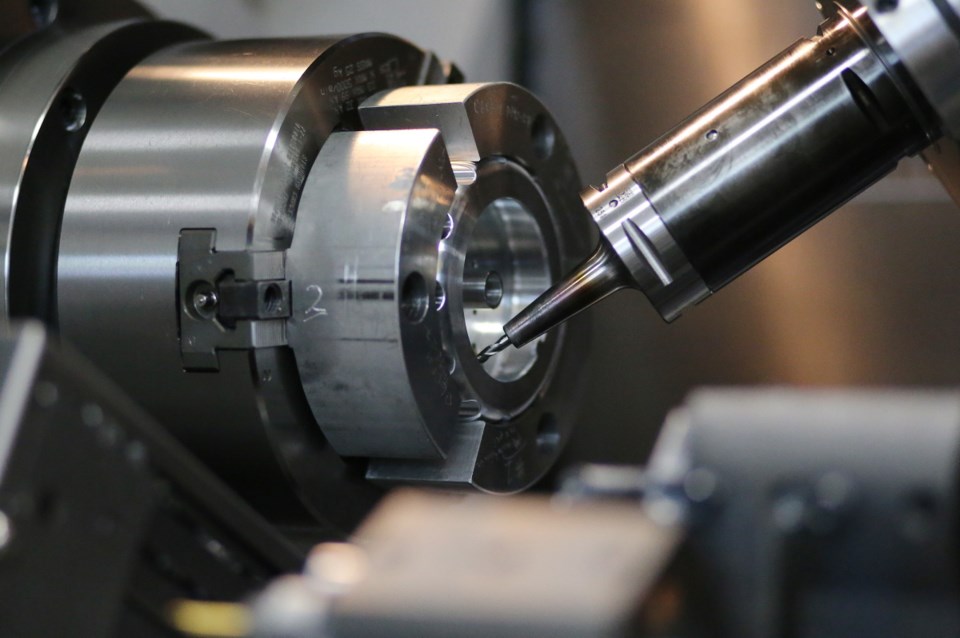

Precision the key

The surf’s up at Anian, a lean — and definitely green — surfboard and apparel manufacturer on the edge of downtown Victoria. Long-time friends and passionate surfers Nick Van Buren and Paul Long, both 26, built their shop at 516 Discovery St., in December. Like any new business, Anian is striving to build its customer base and revenues, but it is also encouraging others to turn on to solar power.

The surf’s up at Anian, a lean — and definitely green — surfboard and apparel manufacturer on the edge of downtown Victoria. Long-time friends and passionate surfers Nick Van Buren and Paul Long, both 26, built their shop at 516 Discovery St., in December. Like any new business, Anian is striving to build its customer base and revenues, but it is also encouraging others to turn on to solar power.

They partly operate on solar now, but hope to be off the grid by the end of the year. To reach that goal, Anian is running a crowdfunding push by selling products to raise $12,000. Long said they want to turn off traditional power sources “to show other people it’s possible.”

Van Buren and Long raised the capital to open Anian through a construction firm they started in 2012. Each Anian owner is responsible for his own product line.

Van Buren makes surfboards selling for between $650 and $1,000. So far, he’s made 75 boards and is working “flat out.” He makes them to order for a customer base in B.C. and Alberta. That market could grow as more boards ride the waves and word travels in the surfing community.

Long designs shirts, jackets and other apparel, sourcing high-quality materials that are sewn by contractors in Victoria and Vancouver. Prices run from $25 to $130.

They are hoping to sell their clothing in retail outlets in Canada and the U.S. Van Buren also plans to make surfboards in fun designs using recycled wood.

(Photo: At Straitline, specialized parts are being machined for Viking Air.)

Recycling rainbows

An emerging Esquimalt company turning out recycled-glass countertops in a rainbow of colours is finding ready local markets for its products.

An emerging Esquimalt company turning out recycled-glass countertops in a rainbow of colours is finding ready local markets for its products.

Long-time friends Kees Schaddelee and Des Carpenter are partners in Vittrium Building Products, which they set up in April 2012.

The main ingredient in their “100-mile countertop” is crushed recycled glass from suppliers in Greater Victoria. A polymer resin binds the glass.

Since Vittrium opened, two employees have been hired. Revenue has almost doubled year-over-year, Schaddelee said. “Things are good. We are, for the most part, pretty busy,” he said. “We are a lean, small operation.”

Most orders are from southern Vancouver Island, but Vittrium is also supplying countertops for Mountain Equipment Co-op’s new energy-efficient head office at False Creek in Vancouver.

Residential work accounts for about 80 per cent of orders.

The countertop is called Environite and is manufactured in a range of colours, including brown sparkles derived from discarded beer bottles.

A light gray, dubbed Finlayson Fog, is the top selling colour.

Most of the company’s sales are direct from the showroom, but Vittrium also works with dealers.

(Photo: Vittrium's material for countertops is made from recycled glass.)